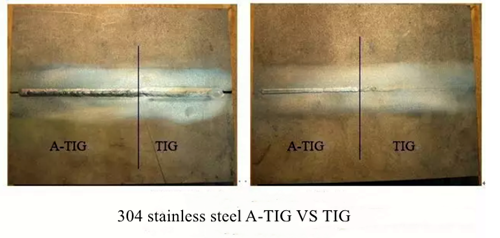

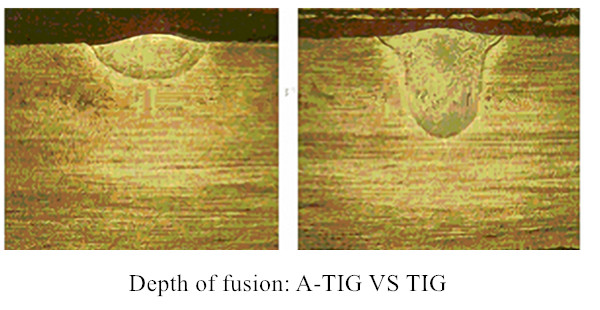

TIG welding also referred to as the “Activate Flux TIG welding”, is the welding process invented by the Ukraine Barton Welding Institute in the 1960s to solve the problem of multi-pass welding. The method is A good way to overcome the disadvantages that common TIG welding depth, material sensitivity. During the welding process, the energy density of the welding arc increases significantly (even more than the energy of the plasma welding arc) under the action of the activate Compared with the common TIG welding method, with the same welding parameters, the activate flux can increase the penetration depth by 2~3 times, reduce the welding time by 50% and increase the welding efficiency by 1~6 times.

A-TIG welding is a kind of substance composition of active agent coated in the base metal welding area of the welded parts, can greatly improve the welding depth, for example, the depth of stainless steel material can be doubled when single-layer welding. At the same time, the upper and lower surface of the weld is wide, while the middle of the weld is narrow, and the dendritic direction is almost the same as the effect of double-sided welding, which is also observed in plasma arc welding. The test results show that A-TIG welding can significantly reduce the weld pass layers and increase the welding efficiency by more than 1 times for thick plates.

At present, A-TIG welding can be used in carbon steel, titanium alloy, stainless steel, nickel-based alloy, copper-nickel alloy in the field of aviation, aerospace, shipbuilding, automotive, pressure vessels and other occasions with higher requirements. The formulation of active flux is the key for A-TIG welding, mainly include oxides, chlorides and fluoride. Different materials have different available active flux components. Compared with conventional TIG welding, A-TIG welding has some advantages showed below:

- Eliminate or reduce the welding depth caused by the change of trace element content and purity during metal smelting; The thermal cracking resistance and cold cracking resistance of the weld metal are improved.

- A-TIG welding process does not groove, no need to fill wire, greatly reducing production costs, and avoid welding quality problems caused by welding wire.

- Improved welding efficiency and surface quality.

When repairing different defects (pores, cracks, etc.), it can directly melt more than 14mm, avoiding grinding, drilling and re-filling metal, thus greatly improving the repair welding efficiency. Compared with TIG welding, the welding seam and heat-affected zone are less than 50%, and the welding deformation is smaller, especially for the thin plate with a thickness of less than 3mm.

- Simple operation and low cost.

Only A-TIG active agent is applied to the surface of the workpiece to be welded before welding. Scrub removal after welding will not pollute the weld seam.

In addition, the active flux can also improve the corrosion resistance of stainless steel welded joints. Compared with traditional welding methods such as arc welding, submerged arc welding, argon tungsten arc welding and melting argon arc welding, A-TIG welding has reliable quality and high production efficiency. Compared with laser welding, electron beam welding and plasma welding, A-TIG welding is also cheaper and more economical because the active flux material is cheaper and only general equipment is required.